|

|

Need a price? Contact our team

Available ATEX and IECEx approved to Ex ia II T4 Ga for use in zones 0, 1 and 2 hazardous environments (gas) and is designed for the on and offshore oil and gas, chemical and other industries with challenging hazardous areas

and is designed for the on and offshore oil and gas, chemical and other industries with challenging hazardous areas

The Straightpoint hazardous area range of Load Measurement Pins (LMP’s) are designed for use in applications where an end of line load cell cannot be used an integrated solution is required.

Often a customised solution they are manufactured from high tensile stainless steel and are normally supplied complete with an anti-rotation plate as a wireless solution with a range of up to 500m or 1640 feet.

Load data is transmitted wirelessly utilising the latest in IEEE 802.15.4 (2.4 GHz) technology providing safe, high integrity, error-free transmission of both static weight and dynamic load to our SW-HHP-ATEX handheld controller for use in hazardous areas.

This latest range of Loadpins utilise easily sourced Energizer® Ultimate Lithium AA Batteries and features advanced circuitry designed to protect the unit from damage associated with incorrectly installed batteries. This advanced circuitry extends battery life eliminates issues associated with rechargeable battery pack charging, failure and replacement.

Note: Please advise cable configuration on order - Radial or Axial Pin exit. ATEX is only available as a wireless option. If you require an ATEX Wireless Load pin to a particular size and design, download our Load pin Questionnaire and return POA.

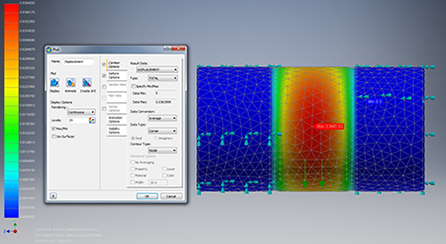

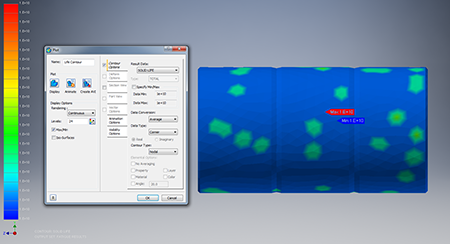

| Typical displacement of a loadpin under full load is around 0.04mm: | The typical lifespan of a 1mv/v loadpin is more than 10 billion cycles: |

|

|

General Description

Loadpin General Description

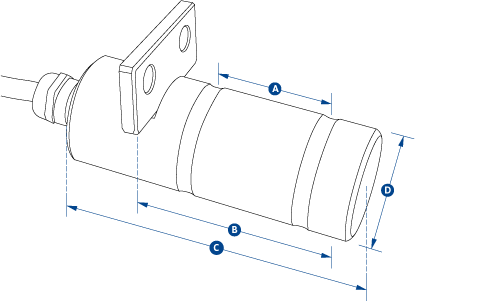

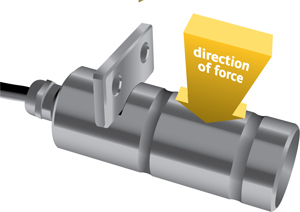

A load measuring pin senses the force applied across it, via strain gauges installed within a small bore through the centre of the pin. Two grooves are machined into the outer circumference of the pin to define the shear planes, which are located between the forces being measured.

Load Pin Environmental Protection

As the instrumented area of the load pin is totally contained within a small central bore, the load pin sensor is inherently waterproof. Manufactured from special stainless steels, fitted with welded or `O' ring sealed end caps and with special attention to the signal cable glanding, a very high operating reliability can be guaranteed even for load pins operating underwater.

- Hazardous areas

- Offshore oil and gas

- Chemical plants

- Proof test certificate

- Operator Manual

- Carry/Storage Case

- Batteries

- 2 year warranty

- Design validated by F.E.A.