Why would you choose one over the other?

Getting the right tool for the job is essential

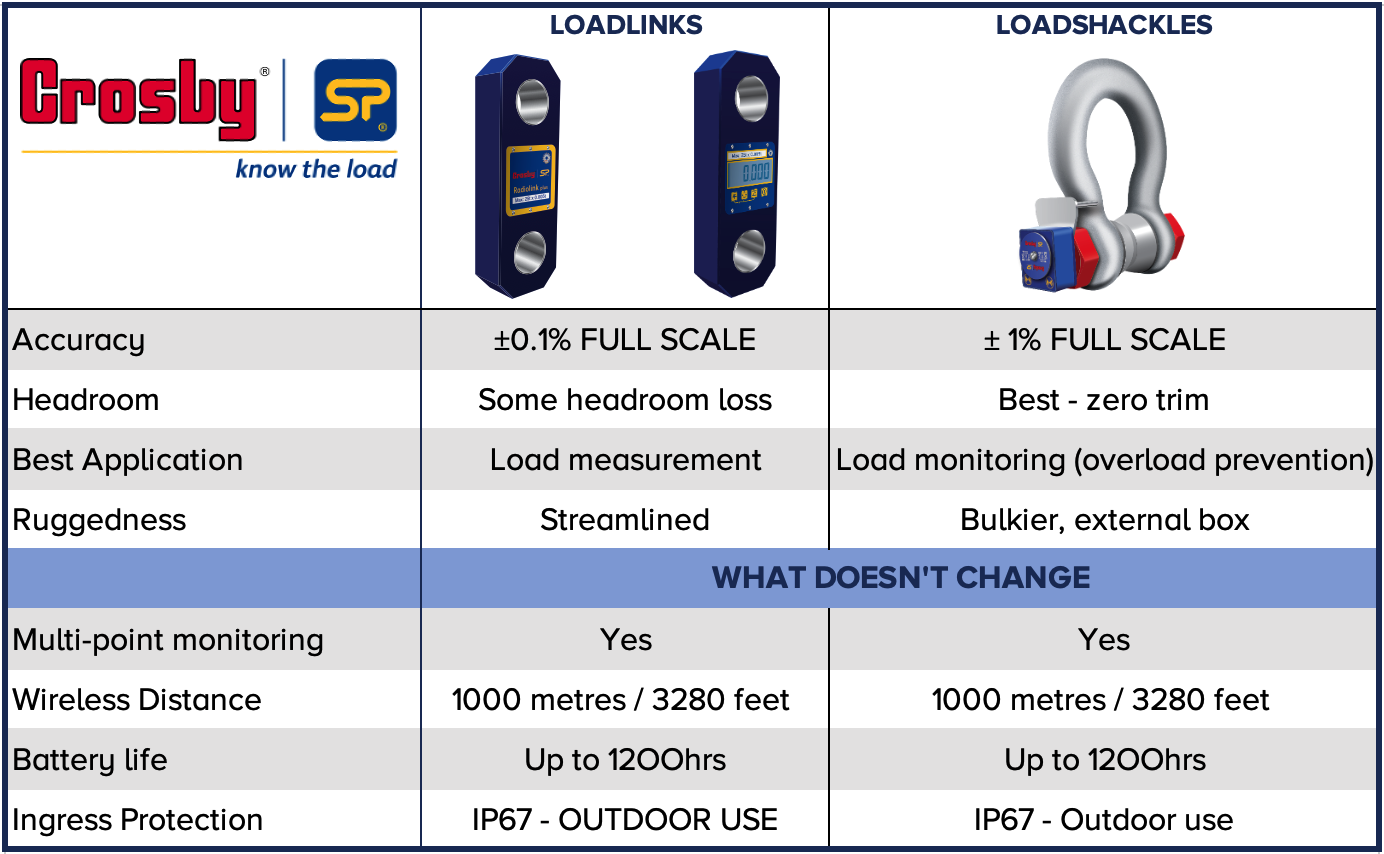

At the simplest level, we could summarise that Loadlinks are for load measurement and Loadshackles are for load monitoring to prevent overload.

Below are some simple criteria to evaluate both options and help you choose the right lifting load cell for your application. At Straightpoint we use the terms ‘loadlink’, ‘dynamometer’ and even 'load indicating device' (LID), they refer to the SP specific name, the generic term and also the term used by ASME B30.26-2010. For the user, there is little or no difference between each.

How they work

First a bit about how they work which will help us understand accuracy.

Loadshackles:

Loadshackles work in shear. During manufacturing, SP removes the pin of a standard bow shackle, bore a hole down the middle and bond strain gauges through the centre of the pin. Now, the shackle pin has become a loadpin.

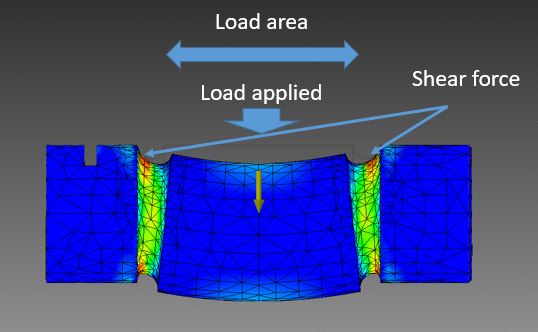

The strain gauges are then aligned with two shear grooves that are visible from the outside of the pin. The groove depth is precisely calculated in terms of position and depth to allow the best Loadpin performance but stay within our strength and safety guidelines. Advanced finite element analysis (FEA) software is used to model and prove our calculations.

The area between those grooves is the ‘load area’. When a load is applied a shear force occurs across those grooves. This shearing effect is measured by the strain gauges which, once the load pin has been calibrated is translated into an actual force or weight reading for the user.

Loadlinks:

Loadlinks work in tension. Strain gauges are bonded to the body of our aluminium load cells. The process of bonding the strain gauges to the load cell body that is flexing under load is similar to load shackles, but in this case, the strain gauges are flexing directly in line with the pull on the load cell, so straight line and in tension.

This direct tension force on the body of the load cell while under load gives us a very clear, linear signal from the strain gauges. This is what gives load links superior accuracy of 0.1% full scale vs load shackles at +/- 1% full scale.

To achieve the best accuracy with a load pin it is essential to use the full ‘load area’ as described above. You will notice that Straightpoint Wireless Loadshackles use a bobbin or collar to achieve this

You can read more about the importance of the bobbin in this article here.

Quick guide comparison table

Advantages of SP Loadshackles

- Limited headroom

A loadlink consists of a top and bottom shackle in addition to the height of the loadlink body itself.

As a result, a load shackle typically uses around 1/3 the headroom of a loadlink. - Handling

For those who do mobile testing and carry around load cells with them, a load shackle gives you a one-piece measuring device and especially for heavier capacities this may offer easier handling.

A simple swap to load monitoring

In a rigging setup, it is easy to swap standard shackles for wireless Loadshackles for a simple load monitoring solution. No change in headroom or configuration.

Advantage of SP Loadlinks

- Accuracy

A Loadlink (+/- 0.1% full scale) is around 3 times more accurate than a Loadshackle (+/- 1% full scale).

As such it is often chosen for weighing applications, precise force measurement or to calibrate other devices such as safe load indicators (SLI’s) on cranes.

Advantages of SP Loadlinks and Loadshackles

- Multi-point lift monitoring

Once Loadlinks or Loadshackles are in place the banksman leading the lift has visibility of the individual load on each, as well as the total load from one display, Handheld plus, Bluetooth App or INSIGHT software. It allows them to lead the lift, giving them confidence and control for heavy lifts and when moving bulky or out-of-gauge cargoes. - Wireless distance

The wireless range for both is a leading, reliable, 1000m or 3280ft from loadcell to handheld plus - Battery life

1200hrs battery life for both Loadlinks and Loadshackles - Ingress protection

Both are environmentally protected to IP67