|

|

Need a price? Contact our team

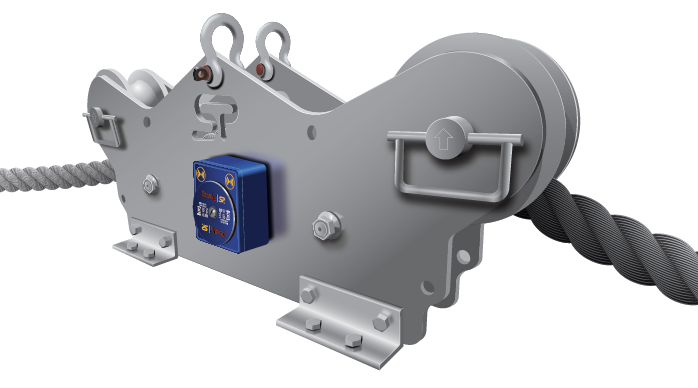

The TIMH range is a Running Line Tensiometer or RLTM built with dockside, marine, offshore, towage and salvage applications in mind. Available with ATEX and IECEx approved to Ex ia II T4 Ga for use in zones 0, 1 and 2 hazardous environments (gas) and is designed for wire rope tension monitoring in applications with challenging hazardous areas.

approved to Ex ia II T4 Ga for use in zones 0, 1 and 2 hazardous environments (gas) and is designed for wire rope tension monitoring in applications with challenging hazardous areas.

All capacities in stock. It is particularly useful where there is no anchor or dead end on the line to rig a Straightpoint Radiolink-ATEX digital dynamometer to measure tension force. The TIMH is constructed from marine grade stainless steel and is suitable for many wire rope configurations up to 80t and will, as an option, calculate lineout in metres or feet along with line speed. The TIMH has several mounting points featured in its unique design but if other mounting options are required Straightpoint can provide a custom-engineered solution specific to your application.

Load data is transmitted wirelessly utilising the latest in IEEE 802.15.4 (2.4 GHz) technology providing safe, high integrity, error-free transmission of both static weight and dynamic load to our SW-HHP-ATEX handheld controller for use in hazardous areas with a range of 500m or 1640ft.

The TIMH utilises easily sourced Energizer® Ultimate Lithium AA Batteries and features advanced circuitry designed to protect the unit from damage associated with incorrectly installed batteries. This advanced circuitry extends battery life and eliminates issues associated with rechargeable battery pack charging, failure and replacement.

- Approved for use in hazardous zones

- Fully constructed from corrosion-resistant stainless steel

- IP67/NEMA6 Loadpin

- Gravity catches fitted to top sheave pins make wire rope installation quick and simple

- Maintenance free heavy duty bearings

- Options for line out available

- Software available to data log and monitor analogue outputs

- Large range of capacities to 80t and wire rope diameters up to 52mm/2”

- Line in/out, distance and speed

- Maintenance free heavy duty needle bearings

- Five-wheel design improving accuracy

APPLICATIONS

- Hazardous areas

- Offshore oil and gas

- Chemical industries

- 2-year warranty

- Design validated by F.E.A.

- Independently approved by CSA

SUPPLIED WITH THE FOLLOWING AS STANDARD

- Proof test certificate

- Operator Manual

- Carry/Storage Crate

Specifications/Technical Data

Wireless Approvals

Federal Communications Commission

FCC: W70MRF24J40MDME

Industry Canada

IC: 7693A-24J40MDME

Japan Certification

ID: 204-52-1

| Part Number | TIMH10TR-ATEX | TIMH25TR-ATEX | TIMH56TR-ATEX | TIMH80TR-ATEX | TIMH150TR-ATEX |

| Crosby Part number | 2789135 | 2789140 | 2789143 | 2789147 | 2789297 |

| Capacity MET | 10 te | 25 te | 56 te | 80 te | 150 te |

| Capacity IMP | 22,000 lb | 55,000 lb | 123,200 lb | 176,000 lb | 330,000 lb |

| Resolution MET | 0.01 te | 0.02 te | 0.05 te | 0.1 te | 0.2 te |

| Resolution IMP | 20 lb | 50 lb | 100 lb | 200 lb | 500 lb |

| Wire rope Ø mm MET | 13-19 mm | 16-26 mm | 28-38 mm | 40-52 mm | 52-89 mm |

| Wire rope Ø mm IMP | 1/2 in - 3/4 in | 5/8 in - 1 in | 1 1/8 in - 1 1/2 in | 1 5/8 in - 2 in | 2 in - 3 1/2 in |

| Weight MET | 91 kg | 87 kg | 82 kg | 77 kg | 231 kg |

| Weight IMP | 200.6 lb | 191.8 lb | 180.8 lb | 169.8 lb | 509.3 lb |

| Approval Spec | Ex ia II C T4 Ga for use in zone 2, 1, and 0 - certificate number IECEx SIR 16.0041X & SIRA 16ATEX2108X | ||||

| Battery Type | 4 x Energizer® Ultimate Lithium AA | ||||

| Battery Life | 1200 hrs | ||||

| Operating Temp MET | -10 to +50 °C | ||||

| Operating Temp IMP | 14 to 122 °F | ||||

| Accuracy | 2% FS | ||||

| Range MET | Wireless version 500 m | ||||

| Range IMP | Wireless version 1640 ft | ||||

| Protection MET | IP67/NEMA6 | ||||

| Max Speed MET | 20 m per minute | ||||

| Max Speed IMP | 65 ft per minute | ||||

| Line out and speed | Not available for ATEX | ||||

| Dimension A MET | 865 mm | 865 mm | 865 mm | 865 mm | 1250 mm |

| Dimension A IMP | 34.05 in | 34.65 in | 34.65 in | 49.21 in | |

| Dimension B MET | 674 mm | 674 mm | 674 mm | 674 mm | 1050 mm |

| Dimension B IMP | 26.53 in | 26.53 in | 26.53 in | 26.53 in | 41.33 in |

| Dimension C MET | 324 mm | 324 mm | 324 mm | 324 mm | 416 mm |

| Dimension C IMP | 12.75 in | 12.75 in | 12.75 in | 12.75 in | 16.37 in |

| Dimension D MET | 111 mm | 111 mm | 111 mm | 111 mm | 153 mm |

| Dimension D IMP | 4.37 in | 4.37 in | 4.37 in | 4.37 in | 6.02 in |