News & Case Studies

- Details

- Written by Administrator

The clamp was flat on the ground, above which the four 50t capacity hydraulic cylinders were positioned along a beam.

SP Compression Load Cell Performs BOP Clamp Load Test

Carl Stahl UAE used four hydraulic cylinders and a wireless compression load cell from Straightpoint (SP) to perform a load test on a blowout preventer (BOP) clamp for an undisclosed client in the Middle East recently.

Carl Stahl, a distributor of SP’s range of force measurement technologies and other lifting equipment, accepted a scope of work to plan and execute a 137.5t load test, and report the findings back to the customer. The BOP in its entirety will be used to stop the uncontrolled flow of liquids and gases during well drilling operations. It is essentially a large, high-pressure valve.

Carl Stahl UAE accepted a scope of work to plan and execute a 137.5t load test.

The clamp was flat on the ground, above which the four 50t capacity hydraulic cylinders were positioned along a beam; above that, the 150t capacity compression load cell was beneath a larger beam rigged to a forklift truck. A shackle at either end of the larger (red) beam connected it to the clamp.

Sinoj Antony, technical manager at Carl Stahl UAE, said: “We used beams to constrain the load within the system and steel plates as footings to spread the load over the surface of the BOP clamp. The forklift was only used to setup the system; the load application was achieved through hydraulic cylinders.”

David Ayling, director at SP, added: “In essence, they [Carl Stahl UAE] spread the lift along the bottom beam and transferred it to the load cell. The same principle could be applied to use of our full range of compression load cells up to 500t capacity.”

David Ayling, director at SP, added: “In essence, they [Carl Stahl UAE] spread the lift along the bottom beam and transferred it to the load cell. The same principle could be applied to use of our full range of compression load cells up to 500t capacity.”

Carl Stahl’s three-person team took readings from the load cell on an SP Hand Held Plus, which allowed them to remain a safe distance from the load. Ayling said therein lied the main advantage of utilising this combination of SP equipment.

“We offer wireless software for data logging of static or dynamic tests,” he said. “The package produces real time load test certification and even boasts centre of gravity software. We also offer a range of base stations that can be used for signal boosting or connection to third-party equipment, such as a PLC with analogue interfaces.”

Carl Stahl’s customers have also noted the absence of troublesome and hard to maintain cables. Antony added that maintenance costs are therefore eliminated and pointed to the product’s versatility in heavy lift, energy, defence, rigging, shipping and other Middle Eastern marketplaces.

He concluded: “We were happy with the performance of the wireless compression load cell and would utilise it again for such an assignment.”

- Details

- Written by Administrator

SP Loadshackle Supports Research at Tree Climbing Championship

A 6.5t capacity wireless loadshackle from Straightpoint (SP) was used to measure loads during competitors’ ascents at this year’s International Tree Climbing Championship (ITCC), which took place 28-30 July at the U.S. National Arboretum in Washington, D.C.

More than 60 of the world’s best male and female professional tree climbers representing 13 countries competed for the title of world champion. The International Society of Arboriculture (ISA) provides training and education on safe work practices for tree care providers; especially for those working aloft. Organized by ISA and presented by The Davey Tree Expert Company, the event was free and open to the public.

The SP Wireless Loadshackle was used in the Ascent Event, which tests a competitor’s ability to efficiently and safely use their selected and approved ascent system. The event assesses competitors’ efficiency in attaching the ascent system to the ascent line(s), ascending to the bell, and transferring into a descent system. The actual descent is not part of the event. Points are earned for speed as well as for meeting predetermined safety objectives.

The SP Wireless Loadshackle was used in the Ascent Event, which tests a competitor’s ability to efficiently and safely use their selected and approved ascent system. The event assesses competitors’ efficiency in attaching the ascent system to the ascent line(s), ascending to the bell, and transferring into a descent system. The actual descent is not part of the event. Points are earned for speed as well as for meeting predetermined safety objectives.

Dr. Brian Kane, Professor of Arboriculture in the Department of Environmental Conservation at the University of Massachusetts in Amherst, explained that the loadshackle was installed between the haul rope and the rigging hub. The ascent lines are attached to an attachment point, controlled by a ground technician using the haul line. Additionally, an overhead belay system is in place and competitors are on belay at all times while aloft.

Kane, who’s university position was endowed by the Massachusetts Arborists Association, was collecting data as part of an ongoing research project supported by the TREE Fund, which works to sustain the world’s urban forests by providing funding for scientific research, education programs, and scholarships related to arboriculture and urban forestry. He said: “This was a convenient event [to gather the data]. I have volunteered at the championships in the past. This was the first time we have used loadshackles in such a way but we will do so again.”

The ITCC showcased arborists in action and helped to educate consumers about professional tree work, and the training and expertise it requires to be carried out safely.

SP’s Wireless Loadshackle provides a solution to limited headroom applications. Each loadshackle is proof tested, then equipped with a hard anodized aluminum electronics enclosure. Kane used the loadshackle with the SW-MWLC software package allowing him to perform load tests at a safe distance, reading data on a laptop.

SP’s Impact Block, which measures the shock load and weight of branches as they are cut during felling or maintenance, is another product targeted at the arborist sector. The load cell is manufactured in partnership with tree safety equipment pioneer DMM. The aesthetic curves of the Impact Block combine with strength and durability to ensure a rope-friendly surface. Utilizing wireless dynamic load monitoring electronics and strain gauge technology, real time data can be displayed on a handheld controller, tablet or laptop. It eliminates the estimation work that often goes into arborist applications.

- Details

- Written by Administrator

Straightpoint to Take Centre Stage at Speedy Expo

Straightpoint (SP) will showcase its range of force measurement equipment and enter its latest innovation for the Star Products award at the Speedy Expo, which takes place 1-2 November at Exhibition Centre Liverpool’s ACC complex in the UK.

Equipment hire firm Speedy staged the event last year on the iconic waterfront and will again combine seminars, an exhibition and networking for suppliers and users of tools, specialist hire equipment, plant and support services. SP will exhibit at Stand F40 in close proximity to the networking zone and Star Products area.

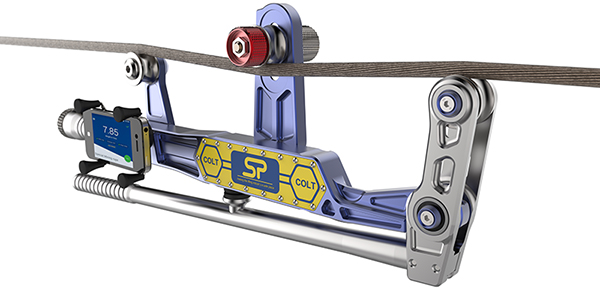

SP will show a full range of equipment, but has chosen one for the award: a new product for measuring tension on static lines—the Clamp On Line Tensionmeter (or COLT)—with a state-of-the-art Bluetooth load monitoring app among a myriad of standout features. Already in Speedy’s hire fleet is SP’s most popular product, the Radiolink plus digital load indicator, but the COLT will be unfamiliar to many visitors.

David Mullard, business development manager at Straightpoint, said: “This is the first time we’ve exhibited at the event. In addition to the [aforementioned] products, we’ll show a 50t Loadlink plus and smaller 5t links to allow visitors to get hands-on with the equipment. Wireless compression load cells will also be part of the product centric exhibit.”

He added: “Speedy is one of our largest UK customers; we have a long-standing relationship over several years. They have for a long time trusted SP Loadlink plus and Radiolink plus dynamometers for safe lifting, LOLER testing, overload prevention and force measurement.”

The Radiolink plus—a 50t version will be on show—is primarily used in weighing, load monitoring and load testing applications. Mullard pointed to key features such as the wireless readout, allowing the user to be a safe distance from the load (up to 700m), and IP67 ingress protection against dust and water. Units take standard AA batteries, facilitating a simple change between hires, and are suited to dynamic testing and monitoring multiple lifting points on one display.

The COLT, meanwhile, is a manual, lightweight tool for measuring wire rope tension on guy wires, cable barriers, overhead lines, fall arrest systems and zip lines. Mullard said users benefit from a lack of cables and lauded its Bluetooth capability. “It’s the most efficient way to measure wire rope tension in the field, store results and send them back to the office, eliminating the need for paperwork,” he added.

The COLT measures tension on wire rope up to 11,000 lbf (lb. force) / 5,000 kgf (kg force) and up to 1 in. / 25mm diameter. It clamps onto pre-tensioned wire ropes, eliminating the need for additional sheaves or tooling, as is the case with alternative solutions.

Mullard said of the state of the UK hire market: “It’s buoyant and dynamic, but always in flux. Speedy has great geographic coverage, a young fleet of rental equipment as well as regional lifting centres of excellence. For the largest customers and projects, Speedy manages on-site facilities to provide the best possible levels of support and service. I expect the expo to provide widespread opportunity to refresh knowledge, make connections, meet contacts and learn.”

Visit SP at Stand F40.

- Details

- Written by Administrator

Compression Load Cells Monitor Weight of Stories Above

Eight 150-ton capacity Straightpoint compression load cells, supplied by Lifting Gear Hire (LGH), were integral to completion of a donor-funded, $18 million transformation project at Washington University’s Olin Library in St. Louis, Missouri.

The project will eventually increase the quantity and variety of seating, study, and research spaces for library users; establish a new north entrance; increase special collections exhibition and storage capacity; and enhance the accessibility and visibility of specialized research services and special collections. Newly created spaces are slated to be open in time for the fall 2017 semester.

The project will eventually increase the quantity and variety of seating, study, and research spaces for library users; establish a new north entrance; increase special collections exhibition and storage capacity; and enhance the accessibility and visibility of specialized research services and special collections. Newly created spaces are slated to be open in time for the fall 2017 semester.

The project included excavation below a café and an expansion of the cafeteria that will provide additional seating, study, and social spaces. New and updated spaces will become a vibrant hub of research expertise and support for faculty, graduate students and undergraduates.

Special Inspections & Design was contacted by fellow St. Louis company Alberici, the general contractor on the project, to support the second, third, and fourth floors of the precast concrete library building.

Steven Fults, principal engineer and co-owner at Special Inspections & Design, explained that three quarters of the building had a below-grade basement but the fourth was concrete slab-on-grade. While excavating soil from beneath the fourth quadrant, it was revealed that the original concrete piers (placed in 1960) did not bear on bedrock, only onto a limestone ledge that was, say, 2 ft. thick.

Thus, Alberici had to shore up ¼ of the building and remove / replace 15 columns while the library stayed in service for students. Fults and his team presented a solution involving 400,000 lb. capacity scaffold towers on each side of these columns with W27 x 109 (depth of 27 in. and a normal weight per foot of 109 lb. f / ft.), 20 ft.-long longitudinal I-beams. Enerpac hydraulic rams, also supplied by LGH, were positioned on each of the four corners to apply load until they matched the dead load of the floors above.

Thus, Alberici had to shore up ¼ of the building and remove / replace 15 columns while the library stayed in service for students. Fults and his team presented a solution involving 400,000 lb. capacity scaffold towers on each side of these columns with W27 x 109 (depth of 27 in. and a normal weight per foot of 109 lb. f / ft.), 20 ft.-long longitudinal I-beams. Enerpac hydraulic rams, also supplied by LGH, were positioned on each of the four corners to apply load until they matched the dead load of the floors above.

Fults said: “The rams shored up the building from under the ceiling of the second floor. We wanted to match at least 90% of the weight or within 1000 lbs. of it. It meant the load cells played an integral role in providing continuous readout of the weight wirelessly to a computer. Each load cell was positioned in the middle of a beam in contact with the ceiling; we energized these beams and they pushed the ceiling upward, adding weight in 1,000, 5,000, or 10,000 lb. increments.”

The SP load cells displayed the actual applied force to the nearest 5 lbs. The latest version of Enerpac’s synchronous lifting system can integrate SP wireless load cell data directly into the controller.

A concrete saw was used to cut the old columns out, at which point that portion of the structure was resting on the load cells and rams connected to a hydraulic pumping unit on a trailer, 200 ft. away. Sometimes the team was working on four columns at a time, hence the requirement for eight load cell units.

Fults said: “When we cut the column out, Alberici demolished the underside with jackhammers, poured a new column foundation with cement, and set a new steel column. We poured high strength grout to fill the gap at the top. Supported by continuous readout from the load cells, we backed the hydraulic rams off slowly.”

He added: “The load cells were like watchdogs; at times all we needed to do was get updates first thing in the morning on elevations and weights. A standout memory from the project was the impact sunlight had. When the sun hit the building, weights fluctuated by several thousand pounds. It was apparent that the reinforced concrete building shifted loads internally within the redundancy of the structure.”

- Details

- Written by Administrator

Load Cell Measures Dredging Line Tension

A 2.5-ton capacity SP Radiolink plus load cell measures tension on a line stretching across a lagoon, upon which a dredge travels at a biosolids management facility, part of the City of Eugene Waste Water Dept., in Oregon, U.S. The RLP was added to inventory at the start of the latest six-month biosolids management season in March, where it replaced a dynamometer that was not suited to working in the elements.

The load cell is connected to a land-based lateral move system that allows the dredge to move from side to side as well as forwards and backwards to harvest biosolids in the lagoon. Biosolids management relates to treated sewage sludge that is intended to be used as soil amendment.

The Radiolink plus boasts a separate internal sealed enclosure providing the load cell's electronic components with IP67 environmental protection even with the battery cover plate missing, making the dynamometer suitable for use in the harshest environments. Measurements are taken on a wireless Hand Held Plus in the cab of the dredge.

Due to the nature of the environment and exposure to corrosive hydrogen sulfide (H2S), SP took extra precautions to protect the delicate strain gauges and electronics by coating the internal components of the load cell with a special epoxy resin resistant to H2S. Contrail Smith, a lead at the biosolids management facility at City of Eugene Waste Water Dept., said, “The dynamometer we were using previously was hard-wired and wasn’t suited to working in the elements.

The RLP gives us both the luxury of wireless information and durability in outdoor application. It’s performed well this season and we’re pleased we found the product during online research during our off-season.” He added, “We monitor the tension on the line as a safety measure; we like to keep the tension around 2,000 lbs. of tension, so the operator keeps an eye on the Hand Held Plus whilst dredging. During the season, the dredge is operational every day for six months—that’s over 180 days—so we need to work with equipment that is reliable; the RLP fits that requirement.” Smith explained that the City of Eugene Waste Water Dept. is likely to be among the first of its kind to apply a load cell to such dredging applications. He said, “We are often visited by our peers from other sites and find that they apply our methods and technologies to their own facilities. I don’t know how many, if any, other sites are using load cells but it’s not likely to be commonplace.”

The lagoons (or ponds) at the facility measure 675 ft. long by 275 ft. wide.