SP would like you to join our global distribution network to represent us in local markets. If you are a quality lifting product supplier and your portfolio can accommodate a world-class range of load cells, there could be avenues of mutual opportunity to explore. We are committed to providing innovative, state-of-the-art products at competitive prices; might that be a proposition you could share with existing and prospective customers?

SP offer the following

Partnership Opportunities

- Growth strategy

– premium product sales with distribution discounts - Raise your company profile

– associate with a leading brand - Engage with our experts

– product, technical & marketing - Industry leading product

– unrivalled specifications & performance - Partnership rewards

– Discounting, co-op & rebate agreements available

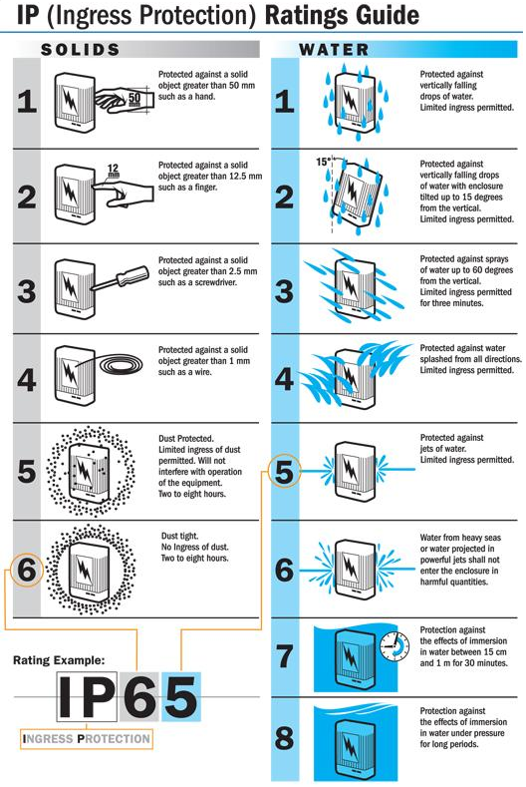

The IP Code (or International Protection Rating, sometimes also interpreted as Ingress Protection Rating*) consists of the letters IP followed by two digits and an optional letter. As defined in international standard IEC 60529, it classifies the degrees of protection provided against the intrusion of solid objects (including body parts like hands and fingers), dust, accidental contact, and water in electrical enclosures. The standard aims to provide users more detailed information than vague marketing terms such as waterproof.

What do the NEMA Ratings mean?

The National Electrical Manufacturers Association (NEMA) is a US Manufacturers Organization which actively promotes

standardized product specifications for electrical apparatus. While NEMA does not actually test products, it establishes the

performance criteria for enclosures intended for specific environments.

Straightpoint products, where stated, are rated either: IP65 (NEMA 4X) IP67 (NEMA 6) or IP68 (NEMA 6P)

IP65 Enclosure - IP rated as "dust tight" and protected against water projected from a nozzle.

IP67 Enclosures - IP rated as "dust tight" and protected against immersion.

IP68 Enclosures - IP rated as "dust tight" and protected against complete, continuous submersion in water.

Most SP loadcells utilise 2.4 GHz direct sequence spread spectrum (DSSS) radio technology which offers high integrity, error free communications that can co-exist with other wireless technologies such as Wi-Fi, Bluetooth® and Zigbee®.

Some applications however require a cabled solution, a great example of this is a subsea application where a loadcell could be mounted many hundreds of metres below the ocean and wireless technology would not work.

Choosing between wired or wireless load cells

The choice between wired or wireless load cells depends on a number of factors but the main ones are application, capacity, convenience and budget.

Application:

Wired load cells suit simple applications. A typical setup is where one load cell is connected to one handheld display (1:1) for a basic readout of the weight. Popular examples would be single-point weighing or when using a load cell in a test bed. But in below the hook applications a loadcell fitted to a crane hook can be cumbersome, easily broken and inhibit the movement of the hook on a crane, Davit or hoist.

More complex applications involving several load cells and showing individual and total loads are more suited to wireless systems. Each wireless load cell transmits a unique ID allowing data to be logged from each cell and alarms can be set if certain maximum or minimum limits are reached. Data logging can be done at speeds up to 200 times per second (200Hz) which suits dynamic testing such as destructive or drop tests.

The SP wireless system uses a proprietary hexadecimal addressing system so other wireless devices in the same location can never cause an incorrect (and dangerous) reading. It can operate on any one of 15 channels offering a solution in rare cases where radio frequency interference (RFI) is experienced.

Capacity and convenience:

Wireless systems allow the user to be a safe distance from the load or from the test being conducted. The higher the capacity involved the more likely the user wants to be away from the load for safety reasons.

Similarly, for convenience, the larger and more awkward an object is the more cables become messy, heavy and obtrusive. They can get snagged, damaged and are a trip hazard – wireless systems not only remove those obstructions but also allow centre of gravity of calculation of an object during weighing – a crucial piece of information when planning a safe lift. Typical structures to be weighed include large fabrications such as pipes, steel plates, precast concrete and offshore jackets for offshore use.

Other factors:

The reliability and convenience of wireless systems has led to those systems being favoured by customers. Around 90% of the systems we sell at Straightpoint are now wireless as customers upgrade from wired systems.

OEM and integrated systems often remain as wired systems. Load information is relayed to a PLC (often via current 4-20mA or voltage 0-5Vdc output). In this scenario, the PLC or Scada system may be monitoring or summing several load cells at one time.

Safety critical applications are usually cabled systems. For example, an entertainment rigging set up with loads transferred above the heads of performers. In this case it is vital high-speed data can transfer to controllers with no possibility of missing wireless data packets or local interference.

All SP loadcells are strain gauged based and use the Wheatstone bridge principle. This article explores the science involved and how a load cell really works.

History

A load cell (or loadcell) is a transducer which converts force or mass into a measurable electrical output, most commonly stated as ## milli volt per volt (mV/V).

Although there are many varieties of force sensors such as hydraulic, piezo and pneumatic strain gauge based load cells are the most commonly used type.

In 1843, English physicist Sir Charles Wheatstone devised a bridge circuit that could measure electrical resistances. The Wheatstone bridge circuit is ideal for measuring the resistance changes that occur in strain gauges. Although the first bonded resistance wire strain gauge was developed in the 1940s, it was not until modern electronics caught up that the new technology became technically and economically feasible.

In 1843, English physicist Sir Charles Wheatstone devised a bridge circuit that could measure electrical resistances. The Wheatstone bridge circuit is ideal for measuring the resistance changes that occur in strain gauges. Although the first bonded resistance wire strain gauge was developed in the 1940s, it was not until modern electronics caught up that the new technology became technically and economically feasible.

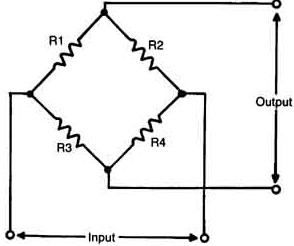

Wheatstone Bridge Circuit

The Science

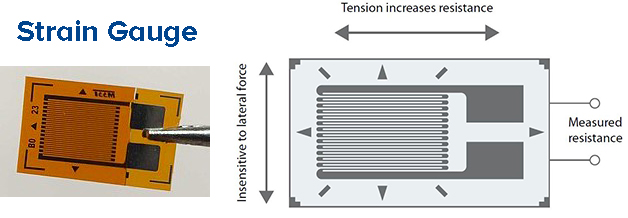

SP Strain gauge loadcells convert the load acting on them into electrical signals. The gauges themselves are bonded onto the loadcell body in carefully calculated positions. When a force is applied the loadcell body deforms.

In most cases, four strain gauges are used to obtain maximum sensitivity and temperature compensation.

Strain gauge

Two of the gauges are usually in tension, and two in compression, and are wired with compensation adjustments to balance zero.

When a load is applied, the strain changes the electrical resistance of the gauges in proportion to the load – SP electronics then amplify and measure this change in proportion and convert it to a display in a known calibrated engineering unit such as tonne, pounds, KiloNewtons or Kilograms allowing the loadcell operator accurate and repeatable measurement.

Types of Load cell

There are several common types of loadcell:

• Loadlink – a block of material with a loading hole for a shackle at each end allowing tensile forces to be applied

• Shear beam - a straight block of material fixed on one end and loaded on the other

• Double-ended shear beam, a straight block of material fixed at both ends and loaded in the centre

• Compression loadcell, a block of material designed to be loaded at one point or area in compression

• ‘S’ beam loadcell, a ‘S’ shaped block of material that can be used in both compression and tension (load links and tension load cells are designed for tension only)

• Shear Loadpin, a round loadcell that senses the force applied across it, via strain gauges installed within a small bore through the centre of the pin. Two grooves are machined into the outer circumference of the pin to define the shear planes.

Excitation and rated output

The Wheatstone bridge is excited with stabilized voltage (usually 3vdc with SP products but could be up to 20v).

The difference in voltage proportional to the load then appears on the signal outputs in mv/v.

A loadcell output is rated in millivolts per volt (mV/V) of the difference voltage at a fully rated mechanical load. So a 2 mV/V loadpin will provide a 6 millivolt signal at full load when excited with 3v.

Typical sensitivity values are 1 to 3 mV/V; most SP load cells are rated around 1.5mV/V.

Four & Six wire load cells

Some load cells have a cable with 4 wires and a screen; others have a cable with 6 wires and a screen. Those with 6 wires, in addition to the +input, -input, +signal and -signal terminations, have 2 wires called +Sense and -Sense. These are sometimes called +Reference (or +Ref) and -Reference (or -Ref).

The main difference in the function of these 2 types is that load cells with a 6-wire cable can compensate for variations in the actual excitation voltage they receive from the amplifier, indicator or PLC. The resistance of an electrical cable (conductor) varies according to its length and any temperature changes, resulting in variations in the excitation voltage at the load cells. With long cables, there will be a drop in voltage from the original value supplied by the amplifier, indicator or PLC and the advantage of a 6-wire load cell is that this drop in voltage can be quickly and effectively compensated without it affecting the load measurement.

4 wire load cells

4 wire load cells are already calibrated and thermally compensated together with the permanent length of cable supplied during their manufacture. SP recommend that you do not shorten the cable of a 4-wire load cell if it is too long; it is better to coil up excess cable. This is because the factory calibration and compensation of a 4-wire load cell will be compromised if you shorten the cable. There are no sense wires to compensate for the new cable length.

When connecting 4-wire load cells together into a junction box before the amplifier, indicator or PLC, we recommend using a dedicated 6-wire load cell cable to connect the junction box to the amplifier, indicator or PLC. This will compensate for any voltage drops over the length of the cable between them. In any event, the cable should be well shielded and have sufficient cross section (at least 0.2 mm sq) to limit the voltage drop along its length.

6 wire load cells

The above precaution about cutting the cables does not apply to load cells with a 6 wire cable. The two sense wires are capable of measuring the actual excitation voltage seen at the Wheatstone bridge inside the load cell, therefore the mV signal from the load cell can be adjusted according to the actual excitation it experiences. If an installation engineer wants to shorten the cables, they can do so without compromising the load cell performance.

Like to know more? Contact our team