| Product Highlight |

|

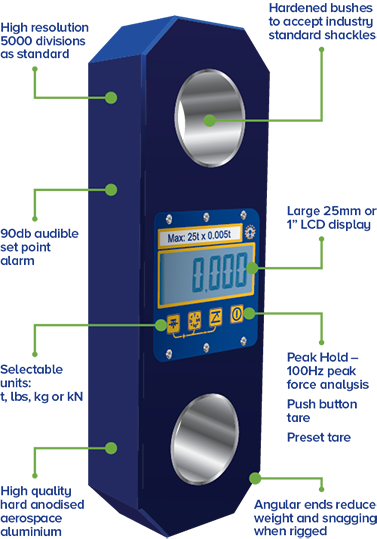

Self Indicating Dynamometer (SID)

Hands free, lightweight dynamometer.

|

FEATURES- Large 1” / 25mm LCD display |

Welcome to Straightpoint - Know The LoadWho we are and our services

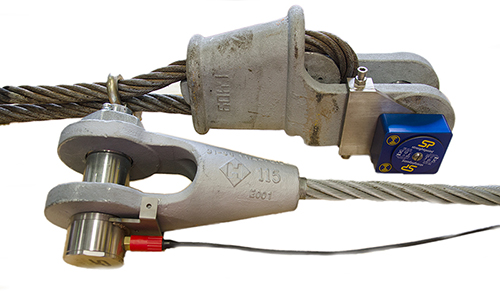

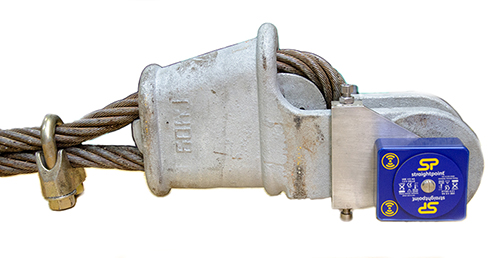

The customisation options provided are so broad that Straightpoint (SP) are also able to produce customised load pins for even ‘Utility Wedge’ and ‘Open Spelter’ type sockets.These types of sockets are often used in conjunction with several wire rope setups including:

Usually made from cast steel, these sockets are designed to be attachment points for wire ropes made of steel. When attached correctly, they are regarded as the strongest fitting types you can use to match the maximum load capacity of the cable. They are also beneficial as an on-site attachment that allows the user to make link connections efficiently. It is usually recommended that an anti-rotation wire rope is used when connecting it to a socket in order to maintain stability of the load whilst attached to the socket. The wire rope’s termination broom is usually held into place inside the spelter socket’s cone with a strong hardening gel. When terminating into a wedge socket, the end of the wire rope is threaded through the cone, bent back around the internal wedge and then gripped into place via a seizing clip.

SP load pins are designed to replace the bolt and cotter pin that are usually used to attach the spelter to a separate line or load.

For flexibility to match a wide variety of requirements, we are able to provide either wireless/radio telemetry (up to 700m remote monitoring) or cabled load pin types (for subsea applications). Both types can be fitted easily and without further modification to the socket. The connection to our hand held monitoring displays (HHP/SW-HHP) is also very simple saving you more time to ensure a safe lift/pull.

Usually made from cast steel, these sockets are designed to be attachment points for wire ropes made of steel. When attached correctly, they are regarded as the strongest fitting types you can use to match the maximum load capacity of the cable. They are also beneficial as an on-site attachment that allows the user to make link connections efficiently. It is usually recommended that an anti-rotation wire rope is used when connecting it to a socket in order to maintain stability of the load whilst attached to the socket. The wire rope’s termination broom is usually held into place inside the spelter socket’s cone with a strong hardening gel. When terminating into a wedge socket, the end of the wire rope is threaded through the cone, bent back around the internal wedge and then gripped into place via a seizing clip.

SP load pins are designed to replace the bolt and cotter pin that are usually used to attach the spelter to a separate line or load.

For flexibility to match a wide variety of requirements, we are able to provide either wireless/radio telemetry (up to 700m remote monitoring) or cabled load pin types (for subsea applications). Both types can be fitted easily and without further modification to the socket. The connection to our hand held monitoring displays (HHP/SW-HHP) is also very simple saving you more time to ensure a safe lift/pull.

|

|

| Cabled Load Pin (above) Ideal for use in subsea applications e.g. pulling loads and for monitoring forces on support lines. |

Wireless Load Pin (above) Ideal for monitoring loads from up to 700m/2300feet away. |

|

|

|

|

|

|

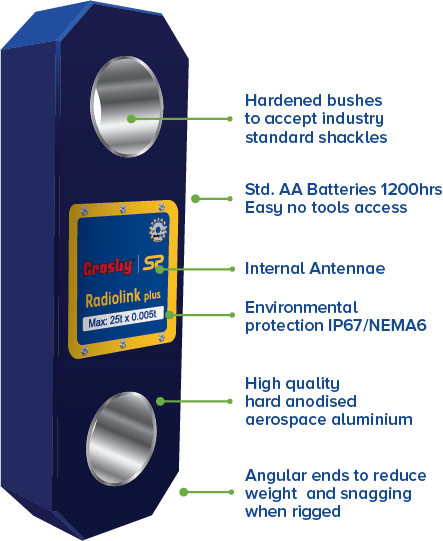

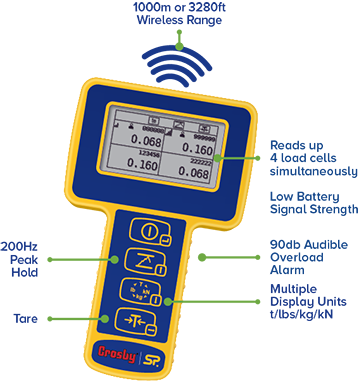

Two versions of the RLP are available:

- Long-range 2.4GHz version providing an industry-leading wireless range of 1000m or 3280ft to SP's SW-HHP handheld or software options.

- Bluetooth output and can be connected to any smartphone running our free HHP app on iOS or Android at ranges up to 100m or 328ft.

Constructed from high-quality aerospace-grade aluminium it features an advanced internal design structure. This design not only provides the product with an unrivalled strength to weight ratio but it also allows the use of a separate internal sealed enclosure providing the load cell's electronic components with IP67 or NEMA6 environmental protection even with the battery cover plate missing, making this industry-leading dynamometer even more suitable for use in the harshest environments.

The versatile RLP is supplied with an update rate of 3Hz and can be easily configured to run at industry-leading speeds of up to 200Hz making it ideal for dynamic force measurement.

Decades of development into this product include many stand out features such as SP's unique strain gauging method that helps compensate for wire rope torque when the Radiolink is loaded. The Radiolink plus tension load cell can also be used in combination with SP INSIGHT software high-speed wireless data logging software allowing for simultaneous control, display and real-time data logging of up to 126 Straightpoint wireless load cells.

A full array of wireless accessories are also available including signal boosters, LED wireless scoreboards and base stations with analogue (4-20mA, 0-10v, 0-5v) or digital (RS232/485, Modbus RTU, and ASCII) outputs.

|

||

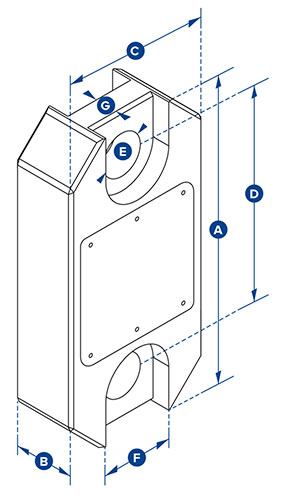

Radiolink plus additional technical data

Wireless ApprovalsFederal Communications Commission

|

|

|

| Part Number | RLP1T | RLP2T5 | RLP6T5 | RLP12T | RLP25T | RLP35T | RLP55T | RLP75T | RLP100T | RLP150T | RLP200T | RLP250T | RLP300T |

| Crosby part | 2789084 | 2789089 | 2789094 | 2789082 | 2789088 | 2789091 | 2789093 | 2789095 | 2789081 | 2789083 | 2789085 | 2789087 | 2789090 |

| Capacity | 1,000 kg | 2.5 te | 6.5 te | 12 te | 25 te | 35 te | 55 te | 75 te | 100 te | 150 te | 200 te | 250 te | 300 te |

| 2,200 lb | 5,500 lb | 14,300 lb | 26,000 lb | 55,000 lb | 77,000 lb | 120,000 lb | 165,000 lb | 220,000 lb | 330,000 lb | 440,000 lb | 550,000 lb | 660,000 lb | |

| Resolution | 0.5 kg | 0.001 te | 0.001 te | 0.002te | 0.005 te | 0.005 te | 0.01 te | 0.01 te | 0.05 te | 0.05 te | 0.1 te | 0.1 te | 0.1 te |

| 1 lb | 2 lb | 2 lb | 5 lb | 10 lb | 10 lb | 20 lb | 20 lb | 100 lb | 100 lb | 200 lb | 200 lb | 200 lb | |

| Units | kg | te | te | te | te | te | te | te | te | te | te | te | te |

| lb | lb | lb | lb | lb | lb | lb | lb | lb | lb | lb | lb | lb | |

| Weight | 1.5 kg | 1.5 kg | 2.4 kg | 3.7 kg | 5 kg | 8.6 kg | 13 kg | 16 kg | 34 kg | 46 kg | 82 kg | 82 kg | 118 kg |

| 3.3 lb | 3.3 lb | 5.3 lb | 8.2 lb | 11 lb | 19 lb | 28.7 lb | 35.3 lb | 75 lb | 101.4 lb | 180.8 lb | 180.8 lb | 260 lb | |

| Safety Factor | 12.1 | 7:1 | 7:1 | 7:1 | 5:1 | 5:1 | 5:1 | 5:1 | 5:1 | 4:1 | 5:1 | 4:1 | 5:1 |

| Battery Type | Handheld - 2 x AA / Loadcell 4 x AA | ||||||||||||

| Battery Life | Handheld - 40 hrs / Loadcell 1,200 hrs continuous (Loadcell 500 hrs if Bluetooth) | ||||||||||||

| Display Type | 240x128 multi-line dot matrix with backlight | ||||||||||||

| Operating Temp | -10 to +50 °C / 14 to 122˚F | ||||||||||||

| Accuracy | ±0.1% full scale | ||||||||||||

| Frequency | 2.4GHz | ||||||||||||

| Range (Max) | 1,000 metres / 3,280 feet (100 m / 328 ft if Bluetooth) | ||||||||||||

| Data Rate | 3Hz - up to 200Hz can be ordered for dynamic load monitoring applications | ||||||||||||

| Protection | IP67 | ||||||||||||

| NEMA6 | |||||||||||||

| Dimension A | 204 | 204 | 249 | 305 | 340 | 393 | 424 | 470 | 608 | 670 | 700 | 700 | 806 |

| 8.03 '' | 8.03 '' | 9.80 '' | 12.01 '' | 13.39 '' | 15.47 '' | 16.69 '' | 18.50 '' | 23.94 '' | 26.38 '' | 27.56 '' | 27.56 '' | 31.73 '' | |

| Dimension B | 43 | 43 | 43 | 47 | 60 | 75 | 75 | 75 | 99 | 99 | 144 | 144 | 150 |

| 1.69 '' | 1.69 '' | 1.69 '' | 1.85 '' | 2.36 '' | 2.95 '' | 2.95 '' | 2.95 '' | 3.90 '' | 3.90 '' | 5.67 '' | 5.67 '' | 5.91 '' | |

| Dimension C | 104 | 104 | 113 | 113 | 115 | 126 | 180 | 202 | 255 | 303 | 350 | 350 | 426 |

| 4.09 '' | 4.09 '' | 4.45 '' | 4.45 '' | 4.53 '' | 4.96 '' | 7.09 '' | 7.95 '' | 10.04 '' | 11.93 '' | 13.78 '' | 13.78 '' | 16.77 '' | |

| Dimension D | 146 | 146 | 165 | 193 | 215 | 225 | 230 | 260 | 320 | 360 | 350 | 350 | 350 |

| 5.75 '' | 5.75 '' | 6.50 '' | 7.60 '' | 8.46 '' | 8.86 '' | 9.06 '' | 10.24 '' | 12.60 '' | 14.17 '' | 13.78 '' | 13.78 '' | 13.78 '' | |

| Dimension ØE | 24.5 | 24.5 | 38 | 47.5 | 55 | 60 | 76 | 76 | 109 | 109 | 145 | 145 | 160 |

| 0.96 '' | 0.96 '' | 1.50 '' | 1.87 '' | 2.17 '' | 2.36 '' | 2.99 '' | 2.99 '' | 4.29 '' | 4.29 '' | 5.71 '' | 5.71 '' | 6.30 '' | |

| Dimension F | 48 | 48 | 65 | Not relevant in this capacity | |||||||||

| 1.89 '' | 1.89 '' | 2.60 '' | |||||||||||

| Dimension G | 19 | 19 | 32 | ||||||||||

| 0.75 '' | 0.75 '' | 1.26 '' | |||||||||||

| Crosby Shackle | G2130 | G2140 | |||||||||||

| Loading Pin Ø | 19 | 19 | 25 | 35 | 51 | 57 | 57 | 70 | 83 | 95 | 121 | 127 | 152 |

| 3/4 in | 3/4 in | 1 in | 1 3/8 in | 2 in | 2 1/4 in | 2 1/4 in | 2 3/4 in | 3 1/4 in | 3 3/4 in | 4 3/4 in | 5 in | 6 in | |

Wireless remote controls, alarms, PC software and LED displays for load sensors to ensure safe, easy and comfortable load cell force monitoring and measurement. Straightpoint's range of wireless accessories may be used with all Straightpoint wireless load cells.

Need a price? Contact our team

![]() SW-BS

SW-BS

Wireless Base Station

The SW-BS is ideal for integration with PLC, SCADA, DAQ or other compatible third-party systems. The device can be configured to provide any of the following outputs as per configuration:

• 4-20mA, Relay setpoint, RS485 ASCII, or optional CANbus 2.0A & 2.0B

![]() SW-SD

SW-SD

Wireless display

This 100mm (4”) scoreboard LED display has a wireless range of 700m/2300ft and is viewable for up to 45m/150ft. Perfect for installation on a crane gantry the unit operates on 100-240 VAC and displays an individual load or summed load for up to eight Crosby Straightpoint Wireless devices.

Order your Crosby shackles alongside your loadlink - wide body available and for more sizes visit Crosby

|

|

|

|

|

| Need a Price? Contact Us |

|

|

|

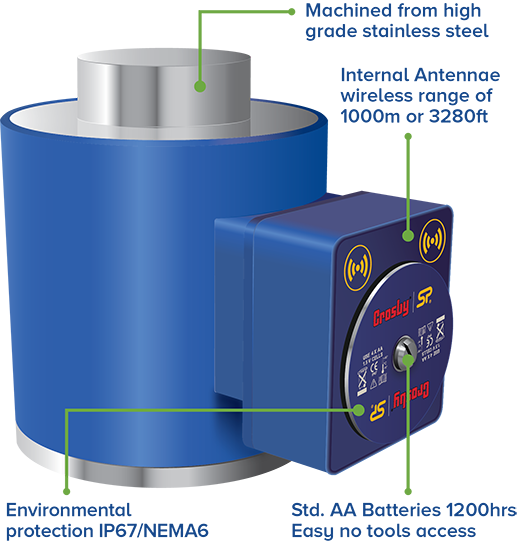

The Straightpoint Wireless Compression LoadSafe (WNI). No longer hindered by troublesome and hard to maintain cables, large scale projects can be completed in a fraction of time previously required. Multiple compression loadcells can all connect wirelessly to our range of PC software via a USB dongle, to our iOS and Android app or to our SW-HHP wireless handheld display.

Maintenance and repair costs are all but eliminated due to the absence of cables and connectors, and the product's flexibility opens the door to a large number of applications in the heavy lift, energy, defence, rigging, shipping, and general transportation sectors.

Two versions of the WNI are available:

- Long range 2.4GHz version providing industry-leading wireless range of 1000m or 3280ft to SP's SW-HHP handheld or INSIGHT software

- Bluetooth output and can be connected to any smartphone running our free HHP app on iOS or Android at ranges up to 100m or 328ft.

Connected to our wireless centre of gravity software (INSIGHT) the WNI loadcell can be used to weigh and verify the centre of gravity of large and heavy objects which may not be evenly proportioned. The system will report weight on each individual loadcell, total weight and C of G in an HTML report based on ISO19901.

Straightpoint’s Wireless Compression Load Cells are machined from high-grade 17-4PH stainless steel, providing excellent strength and corrosion resistance and making them suitable for the most arduous industrial conditions.

|

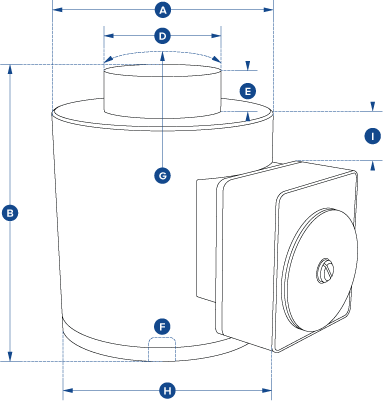

Compression load cell additional technical data

N.B. Clearance of the box may vary from the images displayed depending on the capacity required. |

|

Wireless ApprovalsFederal Communications Commission

|

|

|

Compression load cell specifications |

|||||||||

| Part Number | WNI5TC | WNI10TC | WNI25TC | WNI50TC | WNI100TC | WNI150TC | WNI300TC | WNI500TC | WNI1000TC |

| Capacity | 5te | 10te | 25te | 50te | 100te | 150te | 300te | 500te | 1000te |

| 11,000lb | 22,000lb | 55,000lb | 110,000lb | 220,000lb | 330,000lb | 660,000lb | 110,0000lbs | 2200000lbs | |

| Resolution | 0.001te | 0.002te | 0.005te | 0.01te | 0.05te | 0.05te | 0.1te | 0.2te | 0.5te |

| 2lb | 5lb | 10lb | 20lb | 100lb | 100lb | 200lb | 500lb | 1000lb | |

| Units | tonne | ||||||||

| lbs | |||||||||

| Weight | 6.2kg | 6.2kg | 6.2kg | 6.2kg | 15.5kg | 15.5kg | 65kg | 65kg | 172kg |

| 13.64lb | 13.64lb | 13.64lb | 13.64lb | 34lb | 34lb | 143lb | 143lb | 379lb | |

| Safety Factor | 3:1 | ||||||||

| Battery Type | Loadcell 4 x AA Alkaline | ||||||||

| Battery Life | Loadcell 1200hrs continuous | ||||||||

| Operating Temp | -10 to +50 °C | ||||||||

| 14 to 122˚F | |||||||||

| Accuracy | ±0.1% full scale | ||||||||

| Frequency | 2.4GHz | ||||||||

| Range | 1000 metres (100m if Bluetooth) | ||||||||

| 3280 feet (328ft if Bluetooth) | |||||||||

| Data Rate | 3Hz ( Configurable to 200 Hz) | ||||||||

| Protection | IP67 | ||||||||

| NEMA 6 | |||||||||

| Dimension ØA | 100 | 100 | 100 | 100 | 152 | 152 | 185 | 185 | 362 |

| 3.94 | 3.94 | 3.94 | 3.94 | 5.98 | 5.98 | 7.28 | 7.28 | 14.25 | |

| Dimension B | 127 | 127 | 127 | 127 | 184 | 184 | 300 | 300 | 310 |

| 5.00 | 5.00 | 5.00 | 5.00 | 7.24 | 7.24 | 11.81 | 11.81 | 12.20 | |

| Dimension ØD | 59 | 59 | 59 | 59 | 80 | 80 | 155 | 155 | 270 |

| 2.32 | 2.32 | 2.32 | 2.32 | 3.15 | 3.15 | 6.10 | 6.10 | 10.63 | |

| Dimension E | 16 | 16 | 16 | 16 | 26 | 26 | 27.5 | 27.5 | 40 |

| 0.63 | 0.63 | 0.63 | 0.63 | 1.02 | 1.02 | 1.08 | 1.08 | 1.57 | |

| Dimension F | M18 x 2.5 | M18 x 2.5 | M18 x 2.5 | M20 x 2.5 | M20 x 2.5 | M20 x 2.5 | M20 x 2.5 | M20 x 2.5 | M30x3.5 |

| M18 x 2.5 | M18 x 2.5 | M18 x 2.5 | M20 x 2.5 | M20 x 2.5 | M20 x 2.5 | M20 x 2.5 | M20 x 2.5 | M30x3.5 | |

| Dimension G | 152 | 152 | 152 | 152 | 432 | 432 | 432 | 432 | 950 |

| 5.98 | 5.98 | 5.98 | 5.98 | 17.01 | 17.01 | 17.01 | 17.01 | 37.40 | |

| Dimension H | 158 | 158 | 158 | 158 | 208 | 208 | 241 | 241 | 422 |

| 6.22 | 6.22 | 6.22 | 6.22 | 8.19 | 8.19 | 9.49 | 9.49 | 16.61 | |

| Dimension I | 22 | 22 | 22 | 22 | 33 | 33 | 49 | 49 | 102 |

| 0.87 | 0.87 | 0.87 | 0.87 | 1.30 | 1.30 | 1.93 | 1.93 | 4.02 | |

Wireless remote controls, alarms, PC software and LED displays for load sensors to ensure safe, easy and comfortable load cell force monitoring and measurement. Straightpoint's range of wireless accessories may be used with all Straightpoint wireless load cells.

Need a price? Contact our team

![]() SW-BS

SW-BS

Wireless Base Station

The SW-BS is ideal for integration with PLC, SCADA, DAQ or other compatible third-party systems. The device can be configured to provide any of the following outputs as per configuration:

• 4-20mA, Relay setpoint, RS485 ASCII, or optional CANbus 2.0A & 2.0B

![]() SW-SD

SW-SD

Wireless display

This 100mm (4”) scoreboard LED display has a wireless range of 700m/2300ft and is viewable for up to 45m/150ft. Perfect for installation on a crane gantry the unit operates on 100-240 VAC and displays an individual load or summed load for up to eight Crosby Straightpoint Wireless devices.

![]() SW-SD

SW-SD

Wireless display

This 100mm (4”) scoreboard LED display is wireless and viewable for up to 150 ft. Perfect for installation on a crane gantry the unit operates on 110-240 VAC and displays an individual load or summed load for up to eight Crosby Straightpoint Wireless devices.

|

|

Loadlink plus is designed to be rigged with Crosby standard shackles - digital dynamometer tension load cell known worldwide as the original electronic force measurement device to feature an integral display, the Loadlink plus has been in production since 1979. Over the years the line has been expanded and the Loadlink plus is now used on a daily basis for load monitoring and heavy lifts ranging in capacity from 1t to 300t, by a variety of industrial and commercial industries including manufacturing, transportation, agriculture, oil and gas, utilities, aerospace and clean energy.

Decades of development into this product include many stand out features such as our unique strain gauging method that helps compensate for wire rope torque when the Loadlink is loaded.

This latest version of the digital dynamometer has advanced features and benefits providing solutions for today’s complicated load test and force monitoring needs. The Loadlink plus features full function push button controls for tare, choice of units (lbs, kg, kN, and tonnes), peak hold, preset tare, audible set-point alarm and an overload counter.

The advanced microprocessor based electronics provide the Loadlink plus with high speed read rates, extreme resistance to industrial level noise and unprecedented stability. This high stability gives the Loadlink plus over 5,000 divisions and the highest standard resolution of any digital dynamometer on the market today. Constructed of high-grade aircraft quality aluminium, Straightpoint’s advanced internal design structure allows the product to once again top the charts with an unmatched weight to strength ratio.

Straightpoint’s link style dynamometers are on average 30% lighter than our closest competitor with the same safety rating.

| SP Model | LLP1T | LLP2T5 | LLP6T5 | LLP12T | LLP25T | LLP35T | LLP55T | LLP75T | LLP100T | LLP150T | LLP200T | LLP250T | LLP300T |

| Capacity | 1,000 kg | 2.5 te | 6.5 te | 12 te | 25 te | 35 te | 55 te | 75 te | 100 te | 150 te | 200te | 250 te | 300 te |

| 2,200 lb | 5,500 lb | 14,300 lb | 26,000 lb | 55,000 lb | 77,000 lb | 120,000 lb | 165,000 lb | 220,000 lb | 330,000 lb | 440,000 lb | 550,000 lb | 660,000 lb | |

| Resolution | 0.5 kg | 0.001 te | 0.001 te | 0.002 te | 0.005 te | 0.005 te | 0.01 te | 0.01 te | 0.05 te | 0.05 te | 0.1 te | 0.1 te | 0.1 te |

| 1 lb | 2 lb | 2 lb | 5 lb | 10 lb | 10 lb | 20 lb | 20 lb | 100 lb | 100 lb | 200 lb | 200 lb | 200 lb | |

| Units | te, lb, kg, kN | ||||||||||||

| Weight | 1.5 kg | 1.5 kg | 2.4 kg | 3.7 kg | 5 kg | 8.6 kg | 13 kg | 16 kg | 34 kg | 46 kg | 82 kg | 82 kg | 118 kg |

| 3.3 lb | 3.3 lb | 5.3 lb | 8.2 b | 11 lb | 19 lb | 28.7 lb | 35.3 lb | 75 lb | 101.4 lb | 180.8 lb | 180.8 lb | 260 lb | |

| Safety Factor | 12.1 | 7:1 | 7:1 | 7:1 | 5:1 | 5:1 | 5:1 | 5:1 | 5:1 | 4:1 | 5:1 | 4:1 | 5:1 |

| Protection | IP65 / NEMA 4X | ||||||||||||

| Battery Type | 9v PP3 | ||||||||||||

| Battery Life | 80 hrs continuous | ||||||||||||

| Display Type | 6 digit 25 mm LCD / 6 digit 1 in LCD | ||||||||||||

| Operating Temp | -10 to +50 °C / 14 to 122˚F | ||||||||||||

| Accuracy | +/- 0.1% FS | ||||||||||||

| Dimension A | 204 | 204 | 249 | 305 | 340 | 393 | 424 | 470 | 608 | 670 | 700 | 700 | 806 |

| 8.03 | 8.03 | 9.80 | 12.01 | 13.39 | 15.47 | 16.69 | 18.50 | 23.94 | 26.38 | 27.56 | 27.56 | 31.73 | |

| Dimension B | 43 | 43 | 43 | 47 | 60 | 75 | 75 | 75 | 99 | 99 | 144 | 144 | 150 |

| 1.69 | 1.69 | 1.69 | 1.85 | 2.36 | 2.95 | 2.95 | 2.95 | 3.90 | 3.90 | 5.67 | 5.67 | 5.91 | |

| Dimension C | 104 | 104 | 113 | 113 | 115 | 126 | 180 | 202 | 255 | 303 | 350 | 350 | 426 |

| 4.09 | 4.09 | 4.45 | 4.45 | 4.53 | 4.96 | 7.09 | 7.95 | 10.04 | 11.93 | 13.78 | 13.78 | 16.77 | |

| Dimension D | 146 | 146 | 165 | 193 | 215 | 225 | 230 | 260 | 320 | 360 | 350 | 350 | 350 |

| 5.75 | 5.75 | 6.50 | 7.60 | 8.46 | 8.86 | 9.06 | 10.24 | 12.60 | 14.17 | 13.78 | 13.78 | 13.78 | |

| DimensionØ E | 24.5 | 24.5 | 38 | 47.5 | 55 | 60 | 76 | 76 | 109 | 109 | 145 | 145 | 160 |

| 0.96 | 0.96 | 1.50 | 1.87 | 2.17 | 2.36 | 2.99 | 2.99 | 4.29 | 4.29 | 5.71 | 5.71 | 6.30 | |

| Dimension F | 48 | 48 | 66 | Not relevant in this capacity | |||||||||

| 1.89 | 1.89 | 2.60 | |||||||||||

| Dimension G | 19 | 19 | 32 | ||||||||||

| 0.75 | 0.75 | 1.26 | |||||||||||

| Crosby Shackle | G2130 | G2130 | G2130 | G2130 | G2130 | G2130 | G2140 | G2140 | G2140 | G2140 | G2140 | G2140 | G2140 |

| Loading Pin Ø | 19 | 19 | 25 | 35 | 51 | 57 | 57 | 70 | 83 | 95 | 121 | 127 | 152 |

| 3/4 in | 3/4 in | 1 in | 1 3/8 in | 2 in | 2 1/4 in | 2 1/4 in | 2 3/4 in | 3 1/4 in | 3 3/4 in | 4 3/4 in | 5 in | 6 in | |

Order your Crosby shackles alongside your loadlink - wide body available and for more sizes visit Crosby

|

|

|

Straightpoint load cells are used in many industries such as oil and gas, shipping, construction, renewable energies, lifting and cranes, topside and tie downs, mining, entertainment, water bag testing, breakbulk, utilities and military applications.