|

|

Need a price? Contact our team

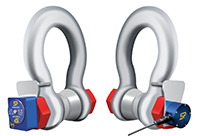

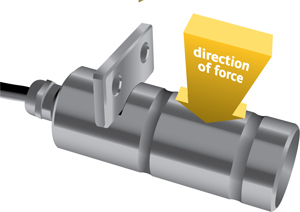

Available from stock in capacities 3.25t to 120t and available up to 1,550t, the Straightpoint Wireless Loadshackle is now available

ATEX and IECEx approved to Ex ia II T4 Ga for use in zones 0, 1 and 2 hazardous environments (gas and is designed for the on and offshore oil and gas, chemical and other industries with challenging hazardous areas. It is manufactured from Crosby’s industry-leading 2130 Carbon and 2140 Alloy Bolt Type Anchor Shackles (3.25te – 120te).

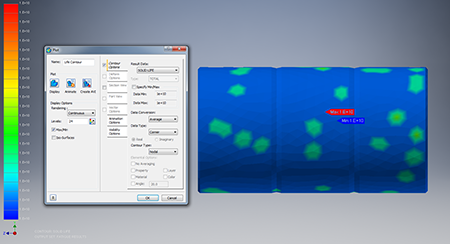

SP's Wireless Loadshackle provides the perfect solution to limited headroom applications. Each Wireless Loadshackle is proof tested, then equipped with a hard anodised aluminium electronics enclosure. Contained within this aluminium enclosure is a new internal chassis providing IP67/NEMA6 environmental protection even with the battery cover plate missing. Featuring industry-leading wireless technology and range, the Wireless Loadshackle is supplied with an update rate of 3Hz and can be easily configured to run at industry-leading speeds of up to 200Hz.

Load data is transmitted wirelessly utilising the latest in IEEE 802.15.4 (2.4 GHz) technology providing safe, high integrity, error-free transmission of both static weight and dynamic load to our SW-HHP-ATEX handheld controller for use in hazardous areas with a range of 500m or 1640ft.

Our huge range of tooling allows us to calibrate in shackle for extra accuracy, unlike many other load cell manufacturers.

- Approved for use in hazardous zones

- Proprietary 2.4 GHz Wireless

- Error-free data transmission

- Wireless range of 500m/1640ft

- Unrivalled Resolution

- Environmentally sealed to IP67/NEMA6

- Unrivalled resolution

- Unmatched Battery Life of 1200hrs

- Low headroom solution

- Hazardous areas

- Offshore oil and gas

- Chemical plants

- 2 year warranty

- Complies with ASME B30.26

- Design validated by F.E.A.

- Independently approved by CSA

SUPPLIED WITH THE FOLLOWING AS STANDARD

- Centralising bobbin

- Proof test certificate

- Operator Manual

- Carry/Storage Crate

Specifications/Technical Data

|

Ex battery type: SAFETY REMINDER |

|

Wireless ApprovalsFederal Communications Commission

|

Global Specifications

| Part Number | WLS3.25T-ATEX | WLS6.5T-ATEX | WLS12T-ATEX | WLS25T-ATEX | WLS55T-ATEX | WLS85T-ATEX | WLS120T-ATEX | WLS200T-ATEX | WLS300T-ATEX | WLS400T-ATEX |

| Crosby Part number | 2789424 | 2789425 | 2789426 | 2789427 | 2789428 | 2789429 | 2789430 | 2789431 | 2789432 | 2789433 |

| Capacity MET | 3.25te | 6.5te | 12te | 25te | 55te | 85te | 120te | 200te | 300te | 400te |

| Capacity IMP | 7150lb | 14300lb | 26400lb | 55000lb | 120000lb | 185000lb | 260000lb | 440000lb | 660000lb | 880000lb |

| Resolution MET | 0.005te | 0.005te | 0.01te | 0.02te | 0.05te | 0.05te | 0.1te | 0.2te | 0.5te | 0.5te |

| Resolution IMP | 10lb | 10lb | 20lb | 50lb | 100lb | 100lb | 200lb | 200lb | 1000lb | 1000lb |

| Units MET | tonne | tonne | tonne | tonne | tonne | tonne | tonne | tonne | tonne | tonne |

| Units IMP | lb | lb | lb | lb | lb | lb | lb | lb | lb | lb |

| Weight MET | 3.8kg | 4.2kg | 9kg | 19kg | 26kg | 86kg | 126kg | 260kg | 405kg | 662kg |

| Weight IMP | 8.4lb | 9.3lb | 19.84lb | 42lb | 57.3lb | 189.6lb | 277.8lb | 573lb | 893lb | 1459lb |

| Safety Factor | 5:1 when used with bobbin | |||||||||

| Approval Spec | Ex ia II C T4 Ga for use in zone 2, 1, and 0 - certificate number IECEx SIR 16.0041X & SIRA 16ATEX2108X | |||||||||

| Battery Type | 4 x Energizer® Ultimate Lithium AA Batteries | |||||||||

| Battery Life | Loadcell 1200 hrs continuous | |||||||||

| Operating Temp | -10 to +50 °C / 14 to 122˚F | |||||||||

| Accuracy | +/- 1% FS | |||||||||

| Frequency | 2.4GHz | |||||||||

| Range MET | 500 m | |||||||||

| Range IMP | 1,640 ft | |||||||||

| Data Rate | 3 updates per second | |||||||||

| Protection | IP67 / NEMA6 | |||||||||

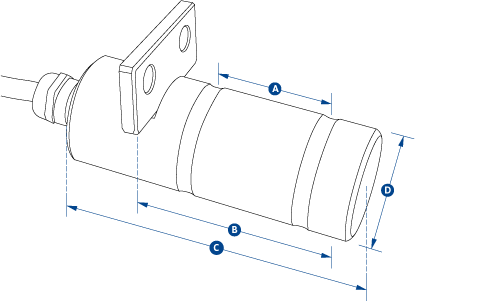

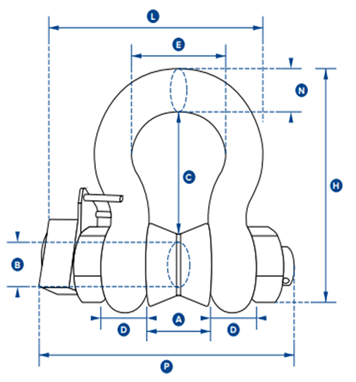

| Dimension A MET | 26.9 | 36.6 | 51.5 | 73 | 82.5 | 127 | 144 | 180 | 205 | 230 |

| Dimension A IMP | 1.06 | 1.44 | 2.03 | 2.87 | 3.25 | 5.00 | 5.66 | 7.09 | 8.07 | 9.06 |

| Dimension ØB MET | 19.1 | 25.4 | 35.1 | 51 | 57 | 83 | 95 | 125 | 150 | 175 |

| Dimension ØB IMP | 0.75 | 1.00 | 1.38 | 2.01 | 2.24 | 3.26 | 3.74 | 4.92 | 5.91 | 6.89 |

| Dimension C MET | 56.9 | 79.7 | 113 | 170 | 189.5 | 317 | 364 | 432.2 | 505 | 547.7 |

| Dimension C IMP | 2.24 | 3.14 | 4.45 | 6.69 | 7.46 | 12.48 | 14.33 | 17.02 | 19.88 | 21.56 |

| Dimension D MET | 14.46 | 20.6 | 29.5 | 44.5 | 51 | 80 | 89 | 110 | 120 | 160 |

| Dimension D IMP | 0.57 | 0.81 | 1.16 | 1.75 | 2.01 | 3.14 | 3.50 | 4.33 | 4.72 | 6.30 |

| Dimension E MET | 42.9 | 58 | 82.5 | 127 | 146 | 190 | 238 | 280 | 305 | 325 |

| Dimension E IMP | 1.69 | 2.28 | 3.25 | 5.00 | 5.75 | 7.48 | 9.37 | 11.02 | 12.01 | 12.80 |

| Dimension H MET | 106 | 148 | 210 | 313 | 348 | 539 | 624 | 769 | 904 | 1006.5 |

| Dimension H IMP | 4.17 | 5.83 | 8.27 | 12.32 | 13.70 | 21.22 | 24.56 | 30.28 | 35.59 | 39.63 |

| Dimension L MET | 135 | 156.5 | 201 | 275 | 306 | 393 | 445 | 529.7 | 586.7 | 667.2 |

| Dimension L IMP | 5.31 | 6.16 | 7.91 | 10.83 | 12.05 | 15.47 | 17.51 | 20.85 | 23.10 | 26.27 |

| Dimension N MET | 17.5 | 24.6 | 35.1 | 57 | 61 | 85 | 95 | 120 | 140 | 160 |

| Dimension N IMP | 0.69 | 0.97 | 1.38 | 2.24 | 2.40 | 3.34 | 3.74 | 4.72 | 5.51 | 6.30 |

| Dimension P MET | 150 | 173 | 222 | 290 | 317 | 448 | 488 | 600 | 657 | 765 |

| Dimension P IMP | 5.91 | 6.81 | 8.74 | 11.42 | 12.48 | 17.63 | 19.21 | 23.62 | 25.87 | 30.12 |

| Crosby Shackle | G2130 | G2140 | S2135 | |||||||

|

|

The ATEX hand control is an intrinsically safe rugged and versatile digital handheld display with a broad range of  features and is suitable for all Straightpoint ATEX/IECEx load cell products. With the option to read up to four SP Ex load cells simultaneously allowing the operator to monitor a multi-pick point lift from a single handheld.

features and is suitable for all Straightpoint ATEX/IECEx load cell products. With the option to read up to four SP Ex load cells simultaneously allowing the operator to monitor a multi-pick point lift from a single handheld.

With a range of 500m or 1640ft enables the user to measure loads from a safe distance in hazardous areas zones 0,1 & 2, such as offshore oil rigs and petrochemical plants

At the heart of the ergonomically designed ATEX Handheld plus is a powerful PCB providing industry-leading features such as user selectable units of measure (tonnes, lbs, kg and kN), peak hold, pre-set tare and an on-screen overload warning and loadcell calibration due warning.

Certification

SW-HHP ATEX

IECEx SIR 15.0072X / Sira 15ATEX2196X

About

- Larger Multiline Screen

- Read up to 4 SP Loadcells simultaneously

- Multiple display units – tonnes, lbs, kg and kN

- On-screen Overload warning

- Loadcell Calibration due warning

- 100Hz Peak hold

- Pre-set tare

- Unrivalled Wireless range 500m/1640ft

- 2 year warranty

SUPPLIED WITH THE FOLLOWING AS STANDARD

- 2XAA Energizer L91

- Operator Manual

|

|

Straightpoint’s expanded range of ATEX products conforms with a new directive—2014/34/EU—that becomes effective today (20 April 2016), updating 94/9/EC.

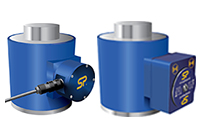

At the turn of the year, the force measurement, load monitoring and suspended weighing load cell equipment manufacturer launched an ATEX and IECEx version of its most popular product, the Radiolink Plus wireless load cell, which met Zone 0, 1 and 2 hazardous area classification.

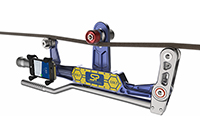

An ATEX version of the wireless Handheld Plus followed, while other wireless products including compression cells, shackle cells, load pins and the Running Line Dynamometer (or TIMH), part of the manufacturer’s tension in motion range, are also in accordance with the 2014/34/EU directive and boast classification in the three-zone, including 0 (an area in which an explosive gas atmosphere is present continuously or for long periods)—unprecedented in wireless below-the-hook force measurement technology.

Need a price? Contact our team  The criteria of ATEX and IECEx are broadly similar, although the former is widely accepted throughout Europe, while the latter is required in many other global markets.

The criteria of ATEX and IECEx are broadly similar, although the former is widely accepted throughout Europe, while the latter is required in many other global markets.

The ATEX version of the load cell and the wireless handheld unit contains several safety components that permit its use in Zone 0 environments. A separate storage area has been created at Straightpoint’s Havant, UK headquarters and all production personnel have been specially trained in the assembly of the explosion-proof units.

EX load cell products available

Radiolink plus | Wireless Loadpin | Wireless Compression | Wireless Shackle | Running Line Tensiometer

Applications

On and offshore oil and gas, chemical and other industries with challenging hazardous areas.

|

|

Need a price? Contact our team

Available ATEX and IECEx approved to Ex ia II T4 Ga for use in zones 0, 1 and 2 hazardous environments (gas) and is designed for the on and offshore oil and gas, chemical and other industries with challenging hazardous areas

and is designed for the on and offshore oil and gas, chemical and other industries with challenging hazardous areas

The Straightpoint hazardous area range of Load Measurement Pins (LMP’s) are designed for use in applications where an end of line load cell cannot be used an integrated solution is required.

Often a customised solution they are manufactured from high tensile stainless steel and are normally supplied complete with an anti-rotation plate as a wireless solution with a range of up to 500m or 1640 feet.

Load data is transmitted wirelessly utilising the latest in IEEE 802.15.4 (2.4 GHz) technology providing safe, high integrity, error-free transmission of both static weight and dynamic load to our SW-HHP-ATEX handheld controller for use in hazardous areas.

This latest range of Loadpins utilise easily sourced Energizer® Ultimate Lithium AA Batteries and features advanced circuitry designed to protect the unit from damage associated with incorrectly installed batteries. This advanced circuitry extends battery life eliminates issues associated with rechargeable battery pack charging, failure and replacement.

Note: Please advise cable configuration on order - Radial or Axial Pin exit. ATEX is only available as a wireless option. If you require an ATEX Wireless Load pin to a particular size and design, download our Load pin Questionnaire and return POA.

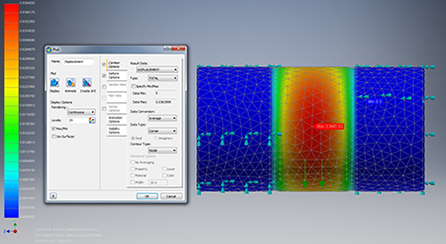

| Typical displacement of a loadpin under full load is around 0.04mm: | The typical lifespan of a 1mv/v loadpin is more than 10 billion cycles: |

|

|

General Description

Loadpin General Description

A load measuring pin senses the force applied across it, via strain gauges installed within a small bore through the centre of the pin. Two grooves are machined into the outer circumference of the pin to define the shear planes, which are located between the forces being measured.

Load Pin Environmental Protection

As the instrumented area of the load pin is totally contained within a small central bore, the load pin sensor is inherently waterproof. Manufactured from special stainless steels, fitted with welded or `O' ring sealed end caps and with special attention to the signal cable glanding, a very high operating reliability can be guaranteed even for load pins operating underwater.

- Hazardous areas

- Offshore oil and gas

- Chemical plants

- Proof test certificate

- Operator Manual

- Carry/Storage Case

- Batteries

- 2 year warranty

- Design validated by F.E.A.